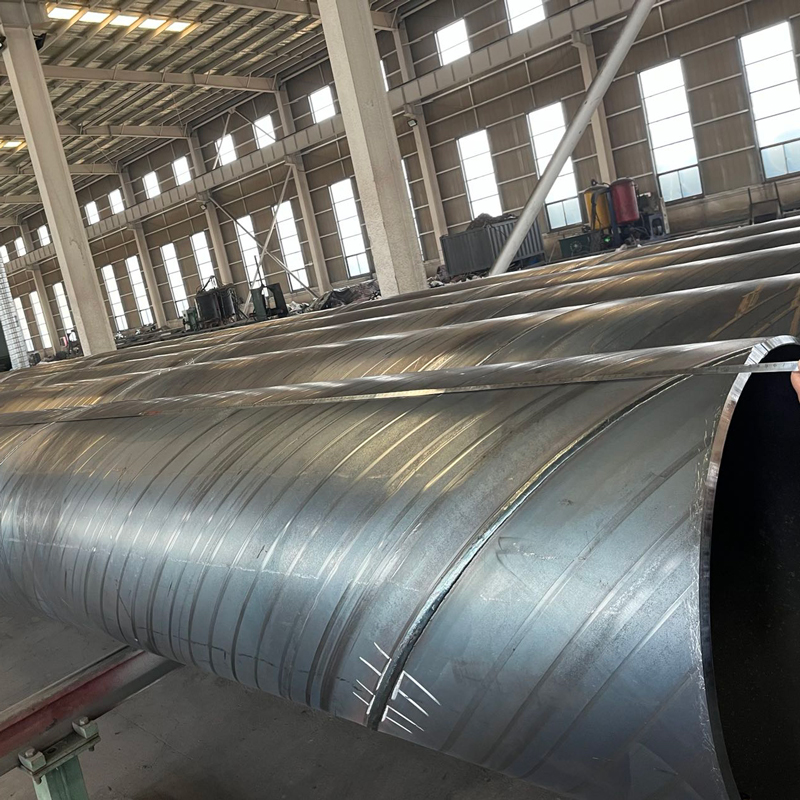

Bututun Layi na Api 5l Grade B zuwa X70 Od Daga 219mm zuwa 3500mm

Kayayyakin Inji na bututun SSAW

| matakin ƙarfe | mafi ƙarancin ƙarfin yawan amfanin ƙasa | mafi ƙarancin ƙarfin tensile | Mafi ƙarancin tsawaitawa |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| X56 | 390 | 490 | 19 |

| X60 | 415 | 520 | 18 |

| X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Sinadarin sinadarai na bututun SSAW

| matakin ƙarfe | C | Mn | P | S | V+Nb+Ti |

| Matsakaicin % | Matsakaicin % | Matsakaicin % | Matsakaicin % | Matsakaicin % | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Juriyar Geometric na bututun SSAW

| Juriyar Geometric | ||||||||||

| diamita na waje | Kauri a bango | madaidaiciya | rashin zagaye | taro | Tsawon dutsen walda mafi girma | |||||

| D | T | |||||||||

| ≤1422mm | −1422mm | <15mm | ≥15mm | ƙarshen bututu 1.5m | cikakken tsayi | jikin bututu | ƙarshen bututu | T≤13mm | T> 13mm | |

| ±0.5% | kamar yadda aka amince | ±10% | ±1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% | 3.5mm | 4.8mm |

Gwajin Hydrostatic

Bututun zai jure gwajin hydrostatic ba tare da yaɗuwa ta hanyar dinkin walda ko jikin bututun ba

Ba sai an gwada mahaɗin ta hanyar amfani da hydrostatic ba, muddin an gwada sassan bututun da aka yi amfani da su wajen yiwa mahaɗin alama cikin nasara ta hanyar amfani da hydrostatic kafin a fara aikin haɗa su.

Bin diddigin abubuwa:

Ga bututun PSL 1, masana'anta za su kafa kuma su bi hanyoyin da aka rubuta don kiyayewa:

Ana nuna yanayin zafi har sai an yi duk gwaje-gwajen chemical masu alaƙa kuma an bi ƙa'idodin da aka ƙayyade.

An nuna asalin sashin gwaji har sai an yi kowace gwajin injiniya mai alaƙa kuma an bi ƙa'idodin da aka ƙayyade.

Ga bututun PSL 2, masana'anta za ta kafa kuma ta bi hanyoyin da aka rubuta don kiyaye asalin zafi da kuma asalin na'urar gwaji ga irin wannan bututun. Irin waɗannan hanyoyin za su samar da hanyar gano tsawon bututun zuwa sashin gwaji da ya dace da sakamakon gwajin sinadarai masu alaƙa.